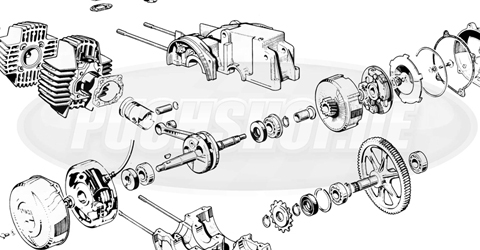

When assembling an Puch, tightening torques are very important, to avoid breaking something or having something too loose. Always tighten with a torque spanner! Below is an overview* of the tightening torques for a Puch moped engine block and frame.

Detailed info

| Tightening torques for Puch E50 engine | Nm | mkp |

| Cylinderhead mounting cast iron cylinder | 10 Nm | 1 mkp |

| Cylinderhead mounting aluminium cylinder | 10 Nm | 1 mkp |

| Flywheel nut | 30 Nm | 3,0 mkp |

| Clutch nut | 27 Nm | 2,7 mkp |

| Crankcase bolts | 8 Nm | 0,8 mkp |

| Flywheel cover | 8 Nm | 0,8 mkp |

| Engine bolts | 32 Nm | 3,2 mkp |

| Tightening torques for Puch frame | Nm | mkp |

| Front and rear axle mounting | 27 Nm | 2,7 mkp |

| Shock absorber bolt top | 23 Nm | 2,3 mkp |

| Shock absorber bolt bottom | 12 Nm | 1,2 mkp |

| Swingarm mounting | 40 Nm | 4,0 mkp |

| Handle bar mounting | 27 Nm | 2,7 mkp |

| Crank mounting | 7 Nm | 0,7 mkp |

Tightening value +/- 10%

1 mkp = ca. 10 Nm

*The tightening torques listed above are for reference only. We are in no way liable for the values listed above.